If you are working with robotics, CNC machines, or 3D printers, you’ve probably used a stepper motor. But have you ever wondered — how are stepper motors actually measured?

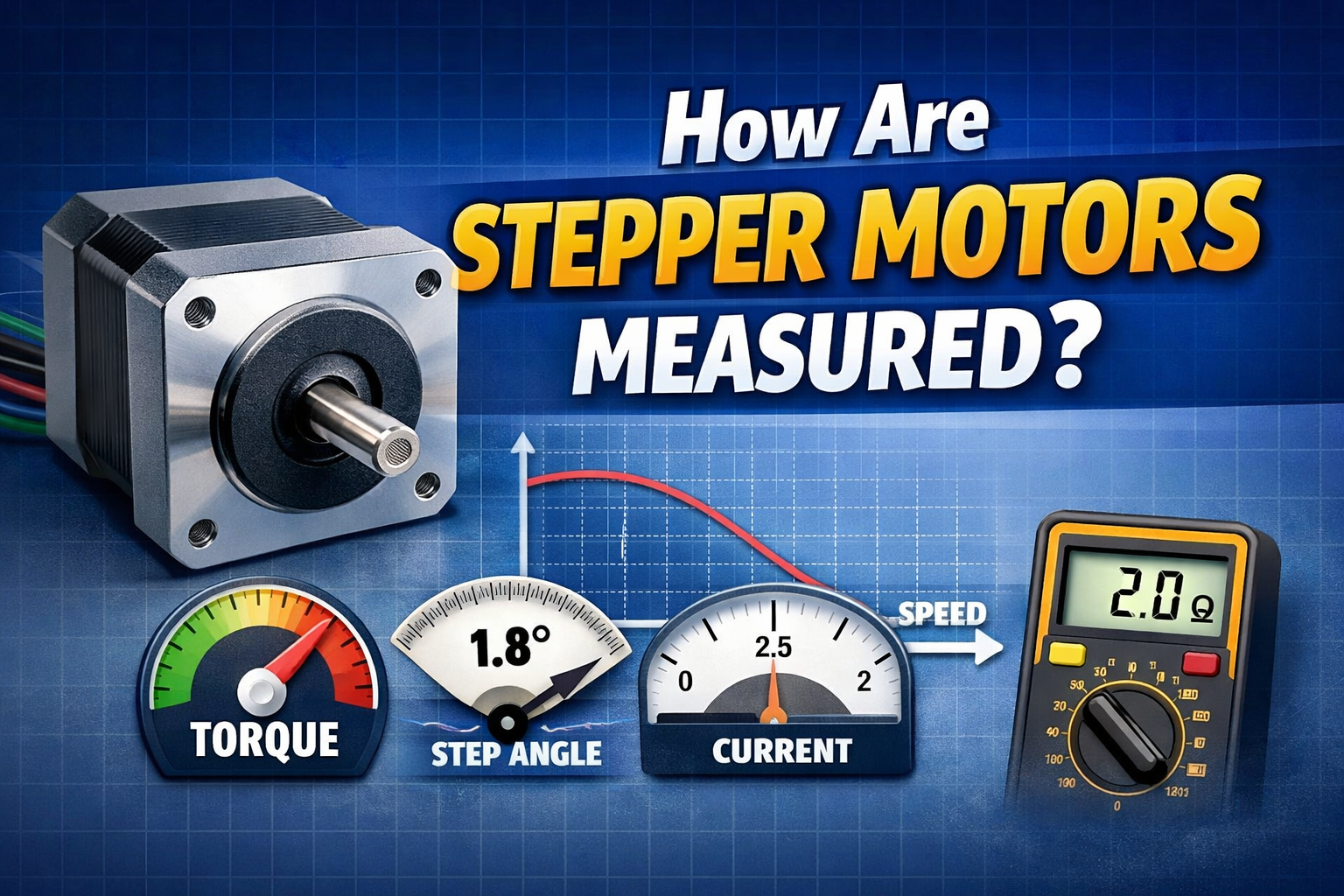

Unlike regular DC motors, stepper motors are not just measured by speed or voltage. They are defined by very specific parameters like step angle, holding torque, current rating, phase resistance, inductance, and positioning accuracy. These measurements determine how precise, powerful, and efficient the motor will be in your project.

Whether you are selecting a NEMA 17 motor for a 3D printer, designing a CNC axis, or building a robotics project, understanding how stepper motors are measured helps you:

• Choose the correct motor

• Avoid overheating or underpowering

• Improve positioning accuracy

• Match the right driver

• Increase overall system reliability

In this guide, we will break down all the important measurements of a stepper motor in simple language — including torque, step angle, current, voltage, resistance, and speed characteristics — so even beginners can understand and confidently select the right motor.

Let’s start by understanding what really defines a stepper motor’s performance.

Parameter to Measure a Stepper Motor

Stepper motors are characterized by various specifications that determine their suitability for specific applications. Understanding how to measure and interpret these specifications is crucial for selecting the right motor for your needs. Here’s a detailed guide on how stepper motors are measured and what these measurements mean:

1. Frame Size

- Description: The frame size of a stepper motor refers to the physical dimensions of the motor, typically measured in millimeters or inches. It is often specified by the NEMA (National Electrical Manufacturers Association) standard, which provides a standard for mounting dimensions.

- Measurement: Frame size is measured across the faceplate of the motor. For instance, a NEMA 17 stepper motor has a frame size of 1.7 inches (43.2 mm) square, while a NEMA 23 has a frame size of 2.3 inches (58.4 mm) square.

- Importance: The frame size helps ensure that the motor fits properly within the mechanical design of your system and matches the mounting requirements.

2. Step Angle

- Description: The step angle is the angle the motor’s rotor moves per step. Common step angles are 1.8°, 0.9°, and 0.72°.

- Measurement: Step angle is a fixed characteristic of the motor and is typically specified in the motor’s datasheet. It determines the resolution of the motor, with smaller angles providing higher resolution.

- Importance: The step angle affects the precision and control of the motor. Smaller step angles offer finer control and higher resolution.

3. Steps per Revolution

- Description: This is the total number of discrete steps required for the motor to complete one full revolution.

- Calculation:Steps per Revolution=360∘Step Angle\text{Steps per Revolution} = \frac{360^\circ}{\text{Step Angle}}Steps per Revolution=Step Angle360∘For example, a motor with a 1.8° step angle:Steps per Revolution=360∘1.8∘=200 steps\text{Steps per Revolution} = \frac{360^\circ}{1.8^\circ} = 200 \text{ steps}Steps per Revolution=1.8∘360∘=200 steps

- Importance: This measurement indicates how many steps the motor takes to complete one full turn, which affects the precision and resolution of the movement.

4. Holding Torque

- Description: Holding torque is the maximum torque the motor can withstand while stationary without moving.

- Measurement: Typically specified in Newton-meters (Nm) or ounce-inches (oz-in) in the motor’s datasheet. This is the torque the motor can hold when it is not rotating.

- Importance: It determines the maximum load the motor can support when stationary and is crucial for applications where holding a position is required.

5. Dynamic Torque

- Description: Dynamic torque is the torque the motor can produce while in motion.

- Measurement: Usually specified in the motor’s datasheet, dynamic torque values vary with speed and are given at different speeds and currents.

- Importance: Dynamic torque impacts the motor’s performance under load while it is operating, affecting how it performs in real-world applications.

6. Current Rating

- Description: This is the maximum current that the motor windings can safely handle.

- Measurement: Typically measured in amps (A) and specified in the motor’s datasheet. It indicates the maximum current the motor can draw without overheating.

- Importance: Proper current rating is essential for selecting a compatible motor driver and ensuring the motor operates safely and efficiently.

7. Voltage Rating

- Description: The voltage rating indicates the nominal voltage at which the motor operates effectively.

- Measurement: Often specified in volts (V) in the datasheet. Note that stepper motors are usually driven with higher voltages than their rated voltage to improve performance.

- Importance: The voltage rating helps in selecting the appropriate power supply and motor driver.

8. Inductance and Resistance

- Description: Inductance and resistance refer to the electrical properties of the motor windings.

- Measurement: Measured in Henrys (H) for inductance and Ohms (Ω) for resistance. These values are specified in the datasheet.

- Importance: These parameters affect the motor’s performance, including how quickly it can respond to changes in current.

Conclusion

Measuring stepper motors involves understanding various specifications, including frame size, step angle, steps per revolution, holding and dynamic torque, current and voltage ratings, and inductance and resistance. Each of these measurements provides insight into the motor’s capabilities and helps in selecting the right motor for your application.