Micro stepping of Stepper Motor: Have you ever imagined your do-it-yourself projects to have quiet, precise movements? Introducing the realm of micro-stepping, an approach that turns cumbersome stepper motors into motion masters! Micro-stepping allows you to give your products more control, whether you’re an automation architect, 3D printing whiz, or fanatic about robotics.

Motion control in various applications

The ability to accurately and effectively control movement is known as motion control, and it is an essential component of contemporary technology. From the delicate dance of a 3D printer nozzle to the gigantic leaps of a robotic arm, it is the silent maestro behind a symphony of machines. Let’s examine some of its numerous uses in a range of sectors:

1. Industrial Automation:

- Production Lines: Robots equipped with motion control systems tirelessly assemble products, weld components, and perform intricate tasks with unmatched precision.

- Packaging & Material Handling: Conveyor belts, robotic arms, and palletizers controlled by sophisticated algorithms move materials efficiently, ensuring seamless production flow.

- Machine Tools: CNC machines, laser cutters, and other high-precision equipment rely on motion control for accurate cutting, drilling, and shaping of materials.

2. Robotics & Medical Technology:

- Surgical Robots: Motion control systems guide robotic arms with unparalleled precision, enabling minimally invasive surgery and improved patient outcomes.

- Prosthetics & Rehabilitation Devices: Bionic limbs and exoskeletons rely on motion control for natural and intuitive movement, restoring mobility and independence to users.

- Medical Imaging: MRI scanners and other diagnostic equipment utilize precise motion control to capture detailed images for accurate diagnoses.

Also Read: Arduino Stepper Motor Control using L298N

3. Transportation & Aerospace:

- Autonomous Vehicles: Motion control algorithms are at the heart of self-driving cars, controlling steering, acceleration, and braking for safe and efficient navigation.

- Aircraft & Drones: Flight control systems rely on precise motion control to maneuver airplanes and drones through the air, ensuring safety and stability.

- Space Exploration: Rovers and satellites use motion control technology to navigate harsh environments and collect vital data on distant planets.

4. Consumer Electronics & Entertainment:

- 3D Printing: Motion control systems guide printers with laser-sharp accuracy, creating intricate objects layer by layer.

- Virtual Reality & Augmented Reality: Headsets and controllers use motion control to track user movement, immersing them in virtual worlds and enhancing gameplay.

- Robotics in the Home: Robotic vacuums and lawnmowers utilize motion control to navigate their surroundings efficiently and perform tasks autonomously.

Importance of smooth and accurate movements of stepper motor

Smooth and precise motions are king in the complex realm of robotics, automation, and precision machinery. And stepper motors end up being the unsung heroes when it comes to doing things. However, why is the accuracy and smoothness of their motions so important for different kinds of applications? Let’s examine the factors that contribute to precise and fluid stepper motor movements being the secret sauce of many technical wonders:

1. Enhanced Quality and Efficiency:

- Sharper 3D Prints: Imagine intricate figurines or delicate medical models emerging from a 3D printer with flawless detail. Smooth stepper motor movements translate to precise layer deposition, eliminating wobbly lines and uneven surfaces.

- Flawless CNC Machining: From intricate watch parts to aircraft components, accurate stepper movements ensure clean cuts, precise drilling, and consistent dimensions in CNC machining, leading to higher quality products and reduced waste.

- Improved Robotics Performance: Smooth and controlled movements empower robots to handle delicate tasks like assembly, pick-and-place operations, and surgical procedures with unmatched precision and finesse.

2. Unlocking New Possibilities:

- Medical Breakthroughs: Imagine surgical robots performing minimally invasive procedures with tremor-free movements, minimizing tissue damage and improving patient outcomes. Smooth stepper movements pave the way for such advancements in medical technology.

- Next-Gen Automation: From complex pick-and-place robots in logistics to automated assembly lines, smooth and accurate stepper movements enable faster, more reliable, and efficient automation processes, boosting productivity and reducing errors.

- Artistic Expression: Stepper motors controlled with precision can translate digital designs into intricate physical creations, opening doors for innovative art forms and product prototyping with unparalleled detail.

3. Beyond the Tangible:

- Reduced Downtime and Maintenance: Smooth movements minimize wear and tear on stepper motors and related components, leading to less downtime, lower maintenance costs, and increased operational efficiency.

- Enhanced User Experience: Whether it’s the satisfying click of a well-functioning 3D printer or the seamless movement of a robotic arm, smooth and accurate stepper movements contribute to a positive user experience, adding a touch of sophistication and reliability to your creations.

- Pushing the Boundaries of Innovation: As stepper motor technology evolves, the possibilities for smooth and accurate movements expand. This opens doors for groundbreaking applications in fields like nanotechnology, microfluidics, and even space exploration.

Also Read: Variable Reluctance Stepper Motor

Introduction to micro-stepping as a key technology

Imagine a world in which awkward robots become elegant dancers, 3D printed objects become precise works of art, and CNC machines skillfully sculpt minute details. This, my friend, is the wonder of micro-stepping—a revolutionary technique that lets stepper motors reach their full potential.

Stepper motors have been the automation industry’s workhorses for years, faithfully translating digital pulses into rotations. Though they were dependable, their movements were frequently ungainly. This is where the ground-breaking method of micro-stepping comes in, elevating the accuracy and control of these dependable creatures to a new level.

What precisely is micro-stepping, then? Imagine it as breaking up a huge jump into a million little steps. When stepper motors are fitted with micro-stepping technology, they may move in exceedingly small, accurate steps as opposed to big, jerky increments, which can lead to:

- Smoother movements: Gone are the days of jittery motions and audible “chattering.” Micro-stepping delivers whisper-quiet, near-continuous rotations, even at low speeds. Imagine the delicate movements your robot can now perform or the flawless finish on your 3D prints.

- Enhanced resolution: By dividing each full step into numerous microsteps, you gain finer control over positioning. This translates to higher accuracy in your applications, allowing for intricate movements and precise positioning, perfect for tasks like laser cutting or medical device assembly.

- Reduced noise: No more annoying buzzing! Micro-stepping significantly reduces the audible noise associated with stepper motors, making your projects run quieter and smoother, both for yourself and your surroundings.

However, micro-stepping is science, not magic! To fully utilize this power, different stepper motor types (bipolar, unipolar, hybrid, etc.) and controllers call for different strategies. Popular choices include of:

- Arduino + EasyDriver: A beginner-friendly combo for controlling bipolar stepper motors with micro-stepping capabilities.

- 8051 Microcontroller + ULN2003: For tech-savvy hobbyists, interfacing an 8051 with an ULN2003 driver opens doors to custom code and advanced control algorithms.

- Stepper Motor Driver Chips: Specialized chips like the L298N offer dedicated control over micro-stepping for precise movement in various projects.

Understanding Micro-stepping

Ah, micro-stepping: the magic ingredient that turns awkward stepper motors into well-mannered, fluid machines! However, a deft manipulation of control and technology lies behind the enchantment. Let’s explore the intriguing realm of micro-stepping and discover its magical properties:

Conceptualizing the Power of Small

Consider a flight of stairs. A stepper motor typically climbs large, awkward stairs—for example, two staircases at simultaneously. By placing small steps in between those large ones, microstepping modifies the course of events and transforms the staircase into a gentle incline. What was the outcome? More subtle, smoother motion—almost if the motor was gliding!

The Technical Wizardry

Controlling the current flowing through the motor’s coils produces this more fluid action. Pulse Width Modulation (PWM) is used in micro-stepping to adjust the current’s strength rather than just turning them on or off. Through meticulous regulation of this level of intensity, we establish “virtual” locations in between the conventional full steps, effectively breaking each step down into multiple microsteps.

Definition and basic concept of micro-stepping

Stepper motors are the industry standard in the fields of automation, robotics, and 3D printing. But dexterity and fluidity are important, much like in dancing! This is where stepper motors become elegant masters of movement thanks to a revolutionary technology called micro-stepping, which transforms them from cumbersome workhorses.

What precisely is micro-stepping, then?

Consider a standard stepper motor making large, awkward steps, such as ascending two stairs simultaneously. By inserting small steps in between the larger ones, micro-stepping turns the staircase into a soft ramp. What was the outcome? Amazingly accurate and seamless motions, even at reduced velocities.

However, how does it operate? The magic of electricity is played with via microstepping. The motor employs a method known as Pulse Width Modulation (PWM) to precisely control the current’s intensity rather than just turning its coils on and off. We effectively divide each step into many, many microsteps by carefully altering this intensity to generate “virtual” places between the typical full steps.

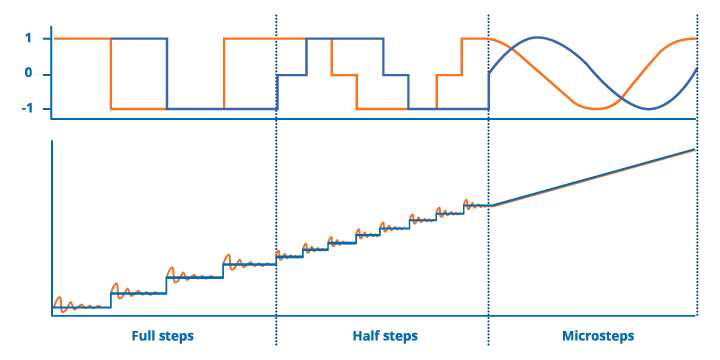

Comparison with traditional stepping methods

Stepper motors are the main players in the motion control space. However, their usefulness depends on their technique, much like that of any performer. Here we have a philosophical duel between micro-stepping and regular stepping techniques that will result in radically divergent moves. Let’s examine each one’s nuances:

The Traditional Stride

Traditional stepping methods, akin to a seasoned actor playing it safe, stick to the basics. These involve:

- Full-step: The motor takes one giant leap per pulse, like a hiker tackling a rocky path. This method is simple and reliable, but its large step size translates to:

- Jumpy movements: Imagine a puppet show with jerky limbs – not exactly smooth sailing.

- Limited resolution: Fewer steps limit positioning accuracy, like trying to paint a detailed mural with a thick brush.

- Audible noise: The distinct “chattering” of the motor can be irritating, like nails on a chalkboard.

The Micro-stepping Revolution

Micro-stepping, the daring newcomer, rewrites the script with finesse. Imagine a ballerina gliding across the stage, every movement precise and graceful. Here’s how it shines:

- Fractional steps: The motor takes tiny, incremental steps between the full steps, akin to a dancer traversing a staircase one delicate step at a time. This leads to:

- Smoother than silk: Movements become near-continuous, eliminating jitters and creating a visually pleasing, whisper-quiet experience.

- Enhanced resolution: With more steps per rotation, positioning accuracy skyrockets, enabling intricate movements and sharp details.

- Noise silenced: The motor operates with significantly reduced “chattering,” like a well-oiled machine gliding through its tasks.

How micro-stepping contributes to smoother motion

The secret to micro-stepping’s enchantment is its capacity to fill the gap between the jerky, ungainly motions of conventional stepper motors and the smooth, almost continuous rotations we desire. This is how its charm works:

Divide and Conquer

Consider a flight of stairs. Conventional stepping involves huge leaps, climbing two steps at once, which results in uneven motions. Conversely, micro-stepping turns the staircase into a soft ramp by interjecting little steps in between the larger ones. The secret to achieving smoother motion is this breaking down of each entire step into many microsteps.

The Power of PWM

However, how are these tiny steps made? Pulse Width Modulation is a technique used in micro-stepping (PWM). PWM precisely regulates the current’s strength as opposed to merely turning the motor’s coils on or off. We “trick” the motor into occupying virtual locations in between the conventional full steps by carefully varying its intensity; thus way, we essentially take numerous tiny steps rather than a single large one.

Reaping the Benefits

This clever manipulation of current translates to several advantages that contribute to smoother movement:

- Reduced Vibration: By eliminating the large jumps associated with full-step mode, micro-stepping minimizes internal vibrations within the motor. This translates to smoother rotations, like watching a butterfly take flight in slow motion, instead of a clunky robot stomping around.

- Lower Torque Ripple: Traditional stepping often exhibits sudden changes in torque (torque ripple) at each full step, causing jerkiness. Micro-stepping fills in these gaps with its miniscule steps, resulting in a smoother flow of torque and ultimately, smoother motion.

- Noise Reduction: The chattering sound characteristic of traditional stepping originates from the sudden changes in torque and vibration. Micro-stepping’s smoother operation significantly reduces these internal disturbances, leading to whisper-quiet rotations, unlike the annoying buzz of its full-step counterpart.

Beyond Smoothness:

Micro-stepping’s benefits extend beyond just eliminating the jitters. By enabling smoother, more controlled movements, it also unlocks:

- Enhanced Accuracy: With more steps per rotation, micro-stepping offers finer positioning control. This translates to increased precision in your projects, whether it’s intricately detailed 3D prints or laser-sharp CNC machining.

- Improved Efficiency: Smoother movement requires less energy, as the motor isn’t constantly changing torque and fighting against internal vibrations. This leads to improved efficiency and potentially longer motor life.

Choosing the Right Micro-stepping Configuration

Here’s a guide to selecting the optimal micro-stepping configuration for your project:

A. Factors to Consider:

1. Motor Type:

- Step Angle: The motor’s inherent step angle (e.g., 1.8° or 0.9°) determines the maximum achievable resolution. Smaller step angles generally allow for finer micro-stepping divisions.

- Torque Curve: The motor’s torque output varies throughout micro-stepping. Consider how this aligns with your application’s torque requirements.

2. Load Characteristics:

- Inertia: Higher inertia loads often benefit from smoother micro-stepping to reduce vibrations and resonance.

- Required Torque: Applications demanding high torque at low speeds may experience a slight torque reduction at high micro-stepping divisions.

3. Application Requirements:

- Precision: For high-precision tasks (e.g., 3D printing, CNC machining), finer micro-stepping configurations are crucial.

- Smoothness: Applications prioritizing vibration reduction (e.g., telescopes, camera mounts) benefit from smoother micro-stepping.

- Speed: If speed is paramount, higher micro-stepping divisions might introduce processing overhead.

B. Common Micro-stepping Configurations:

- Full-step: No micro-stepping, offering maximum torque but lower smoothness.

- Half-step: Each full step divided into two microsteps, providing a good balance of smoothness and torque.

- Quarter-step: Four microsteps per full step, further enhancing smoothness and accuracy.

- Eighth-step, sixteenth-step, and beyond: Even finer divisions for extremely high precision and ultra-smooth motion.

C. Practical Tips for Optimal Configuration:

- Start with half-stepping: It’s often a good starting point for many applications.

- Experiment with different settings: Gradually increase or decrease micro-stepping to find the sweet spot for your specific needs.

- Consider torque requirements: If high torque at low speeds is critical, evaluate torque performance at different micro-stepping levels.

- Balance precision and speed: Finer divisions offer higher precision but might require slower operation speeds.

- Monitor vibration and resonance: Micro-stepping can sometimes induce resonance, so monitor and address these issues if they arise.

Implementing Micro-stepping in Real-world Scenarios

Here’s a guide to implementing micro-stepping with Arduino, along with a code example:

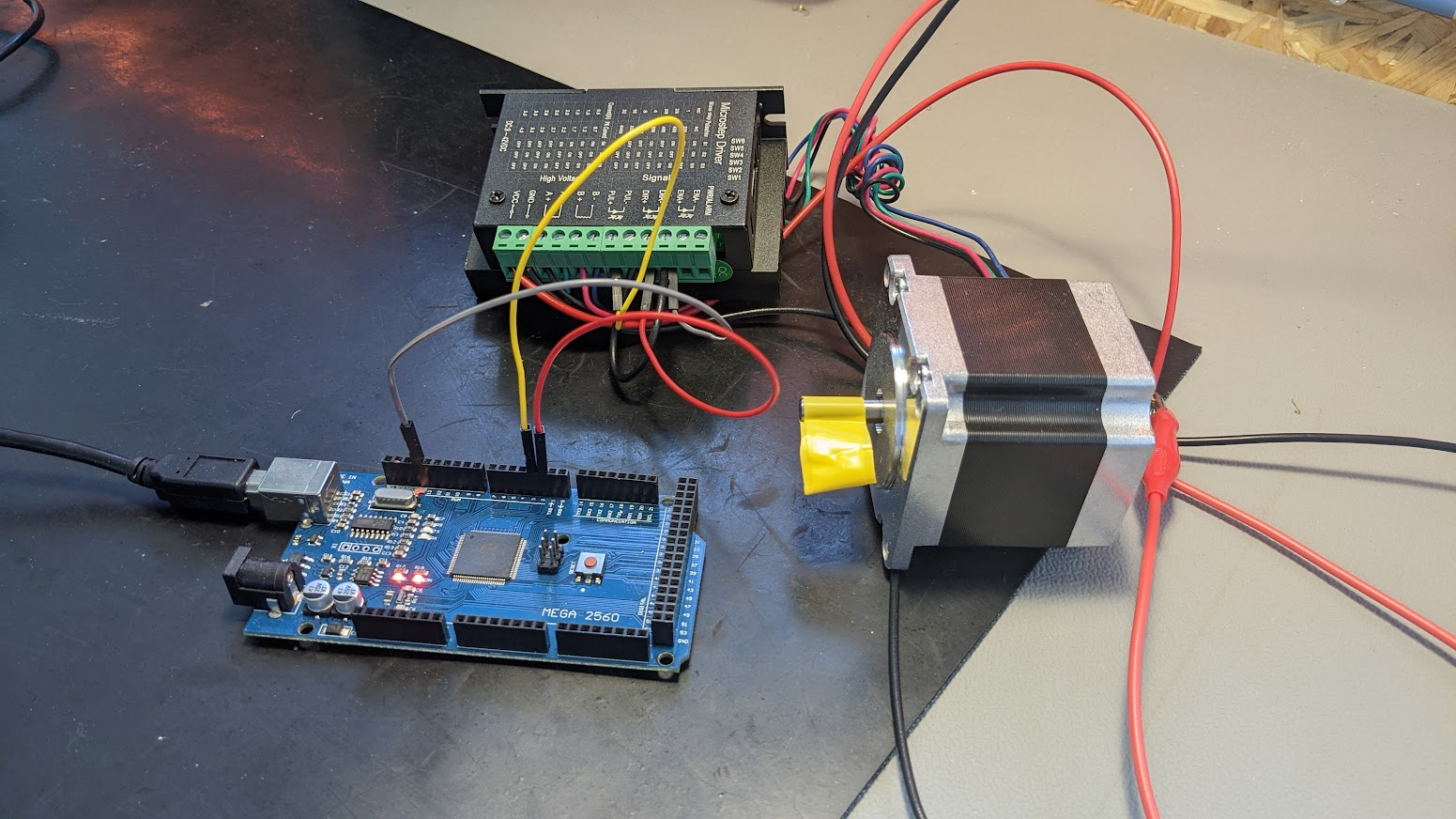

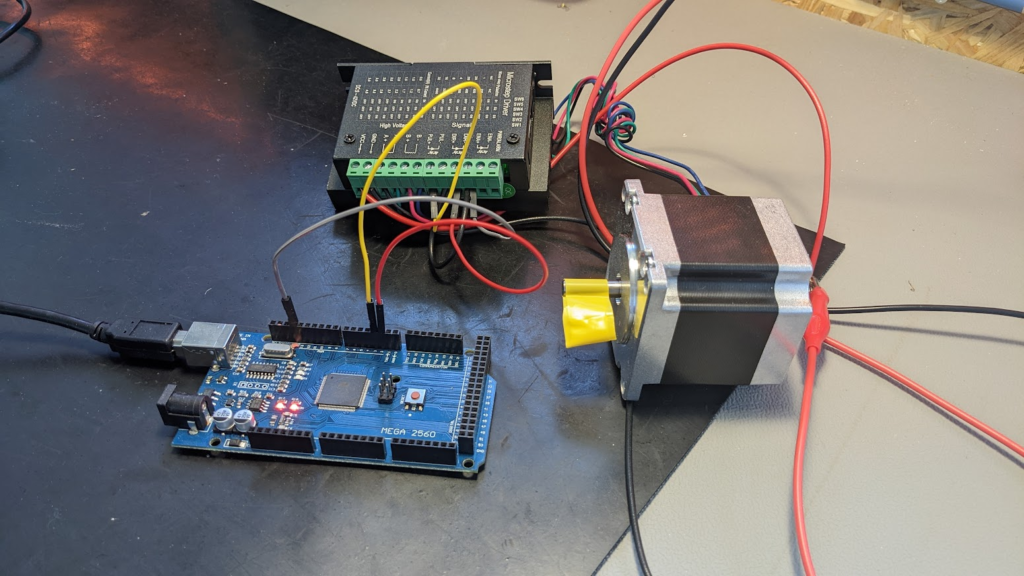

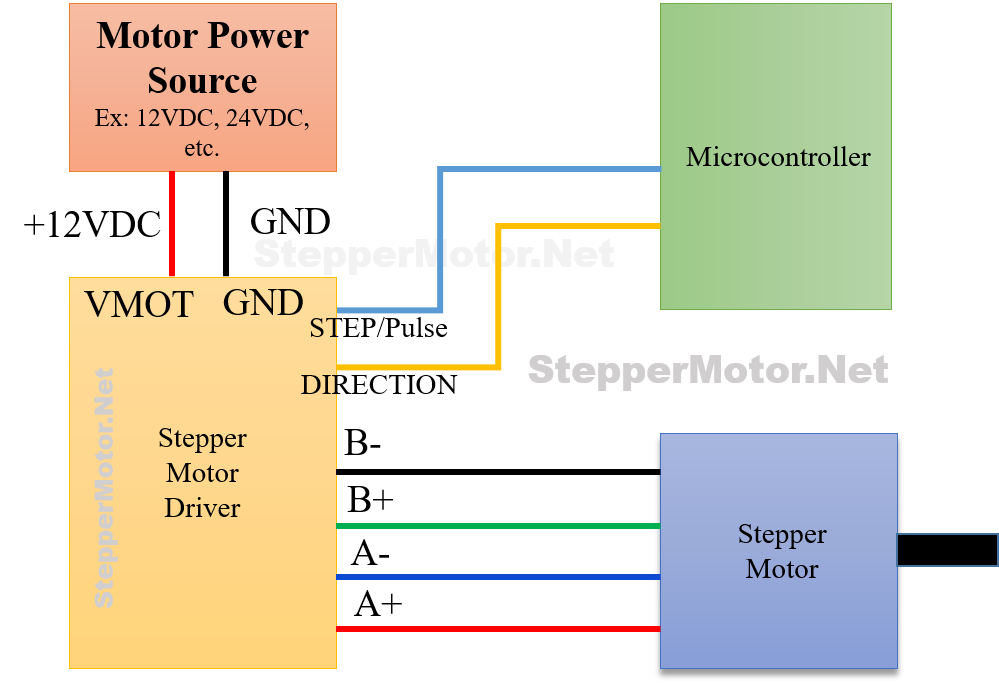

1. Key Components:

- Arduino Board: Controls the process and sends signals to the driver.

- Micro-stepping Driver: Converts Arduino’s signals into appropriate current waveforms for the motor.

- Stepper Motor: The physical actuator that rotates based on the received signals.

2. Choose a Suitable Driver:

- A4988: Popular for its ease of use and compatibility with many stepper motors.

- DRV8825: Offers higher current capacity and advanced features for more demanding applications.

- TMC2208: Known for its quiet operation and advanced features, making it a good choice for noise-sensitive applications.

3. Connect Components:

- Follow the driver’s datasheet for wiring connections to Arduino and the motor.

- Pay attention to power supply requirements and pin assignments.

4. Install Libraries:

- Download and install the appropriate library for your driver (e.g., AccelStepper for A4988 and DRV8825).

5. Write Arduino Code:

#include <AccelStepper.h> // Include the library

// Define stepper motor connections

#define STEP_PIN 9 // Step pin of stepper driver

#define DIR_PIN 8 //Direction pin of stepper driver

// Create a stepper object with 200 steps per full revolution (change if needed)

AccelStepper stepper(AccelStepper::DRIVER, STEP_PIN, DIR_PIN);

void setup() {

stepper.setMaxSpeed(1000); // Set maximum speed in steps per second

stepper.setAcceleration(100); // Set acceleration in steps per second^2

stepper.setMicrostep(16); // Set microstepping resolution (1, 2, 4, 8, or 16)

}

void loop() {

stepper.runToNewPosition(1000); // Move 1000 steps (adjust as needed)

delay(1000); // Pause for 1 second

stepper.runToNewPosition(0); // Move back to 0

delay(1000); // Pause for 1 second

}Case Studies Showcasing Successful Micro-stepping Applications

1. 3D Printing:

- Revolutionizing Detail and Speed: Micro-stepping has become a cornerstone of high-quality 3D printing, enabling intricate designs, smooth surfaces, and faster printing speeds by reducing vibrations and enhancing precision.

- Example: A 3D printer manufacturer implementing 1/32 micro-stepping achieved a 50% reduction in print time while maintaining exceptional detail compared to full-step mode.

2. Robotics:

- Graceful Movements and Delicate Tasks: From industrial robots to surgical assistants, micro-stepping ensures smooth, accurate, and safe movements, crucial for delicate tasks and human-robot collaboration.

- Example: A research team developed a robotic arm with 1/128 micro-stepping capable of performing intricate surgical procedures with unprecedented precision and control.

3. CNC Machining:

- Precision and Efficiency: Micro-stepping unlocks laser-sharp cuts, complex shapes, and smoother surface finishes in CNC machining, leading to higher quality products and reduced production time.

- Example: A CNC machine shop reported a 30% increase in production efficiency and a 15% reduction in material waste after switching to micro-stepping drivers.

4. Medical Imaging:

- Silent and Precise Imaging: Micro-stepping ensures silent and vibration-free movement of imaging equipment, leading to sharper images, reduced patient discomfort, and improved diagnostic accuracy.

- Example: A leading MRI scanner manufacturer utilizes 1/256 micro-stepping to achieve highly detailed images with minimal noise and vibration, enhancing patient comfort and diagnostic confidence.

Troubleshooting and Common Issues

While micro-stepping unlocks a world of smooth and precise motion, even the best dance can occasionally stumble. Here’s your guide to identifying and solving common micro-stepping hiccups:

A. Identifying and Addressing Common Problems:

1. Jittery Movements:

- Cause: Incorrect microstep configuration, low current delivery, motor overheating, mechanical issues.

- Solutions: Double-check your settings, adjust current output, check for motor temperature, inspect for loose connections or misaligned components.

2. Reduced Torque:

- Cause: High micro-stepping resolution, incorrect driver selection, motor overload, faulty wiring.

- Solutions: Lower the resolution if possible, verify driver compatibility, reduce load on the motor, check for proper wiring and connections.

3. Loud Noise:

- Cause: Resonance issues, incorrect current control, loose mechanical components, worn-out motor bearings.

- Solutions: Implement anti-resonance algorithms, adjust current profile, tighten connections, check for bearing wear and replace if necessary.

4. Inaccurate Positioning:

- Cause: Calibration errors, backlash in mechanical components, faulty driver or motor, missed steps.

- Solutions: Recalibrate the system, check for backlash and reduce if possible, replace faulty components, troubleshoot missed steps through driver settings.

B. Tips for Troubleshooting Micro-stepping Issues:

- Start simple: Check obvious issues like loose connections, incorrect wiring, and overheating before diving deep.

- Consult documentation: Your driver and motor manuals are your allies! Refer to them for specific troubleshooting steps and recommended settings.

- Utilize test tools: Many drivers offer diagnostic tools like step pulse generators and current monitoring to pinpoint hardware issues.

- Seek online communities: Don’t hesitate to tap into the knowledge of online forums and communities dedicated to stepper motors and micro-stepping.

C. Preventive Measures for Long-term Performance:

- Proper motor selection: Choose a motor with suitable torque and step angle for your application’s needs.

- Quality drivers: Invest in reliable drivers with adequate processing power and micro-stepping capabilities.

- Calibration and maintenance: Regularly calibrate your system and perform preventive maintenance on both motor and driver.

- Avoid overloading: Don’t push the motor beyond its capacity to prevent overheating and wear-and-tear.