Controlling a stepper motor with a Raspberry Pi is a powerful way to bring precision and automation to your projects. This comprehensive guide covers everything you need to know to get started, from understanding the basics of stepper motors to detailed instructions on wiring and programming. Learn how to interface stepper motors with your Raspberry Pi using popular motor drivers like L298N, TB6600, and A4988. With step-by-step wiring diagrams, Python code examples, and tips on circuit protection and power supplies, you’ll be equipped to control stepper motors with ease and accuracy. Whether you’re a hobbyist or a professional, mastering stepper motor control with a Raspberry Pi can open up endless possibilities for your DIY projects and automation systems.

Overview of Stepper Motors

Stepper motors are versatile and precise electromechanical devices used in a wide range of applications, from 3D printers to robotics and CNC machines. Unlike traditional DC motors, which rotate continuously when power is applied, stepper motors move in discrete steps, allowing for exact positioning and controlled rotation.

Stepper motors come in various configurations, but the most common types are unipolar and bipolar. Unipolar stepper motors have six or five wires and are simpler to control, whereas bipolar stepper motors, with four wires, provide better torque and performance. The primary advantage of stepper motors is their ability to position accurately without the need for feedback systems, making them ideal for applications requiring precise movements.

Parts/Components

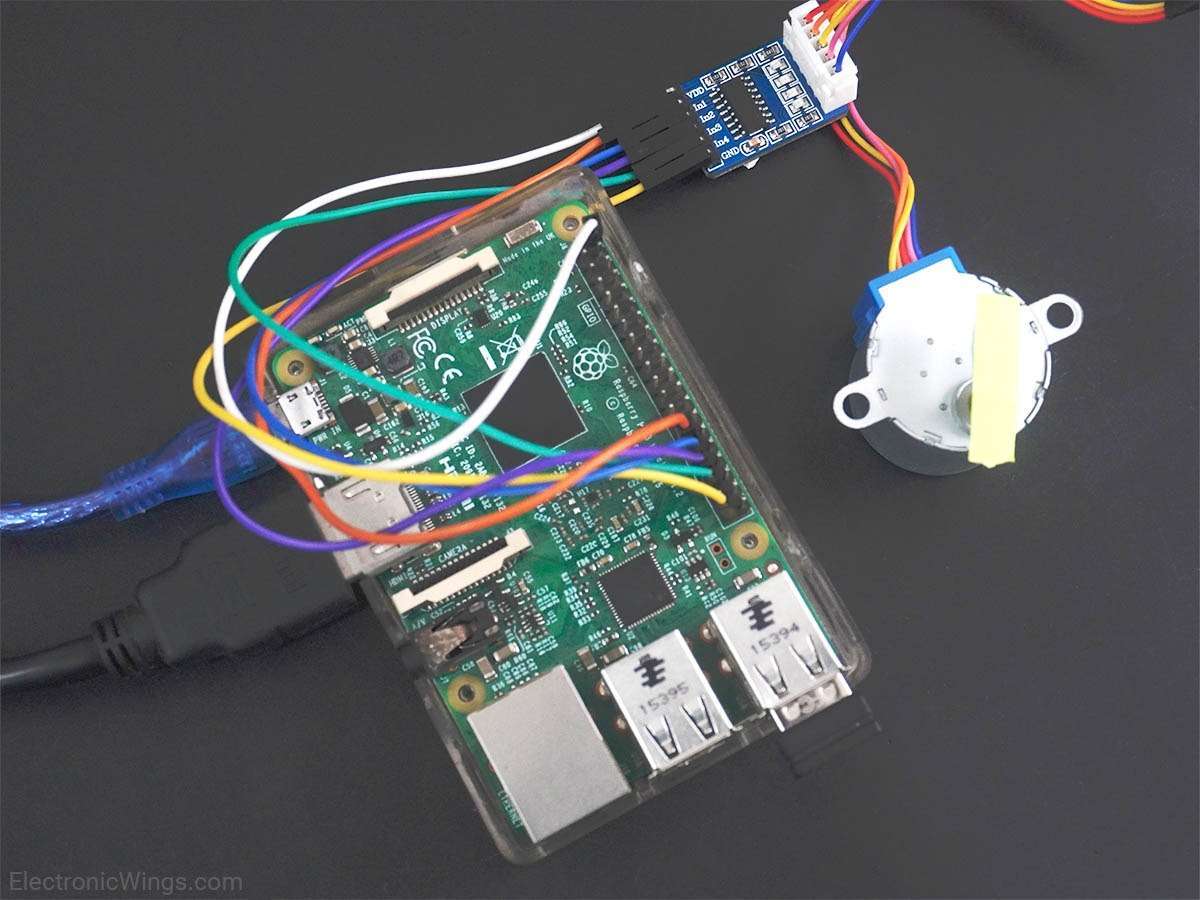

Before diving into the connection diagrams and Python programs, let’s outline the components needed for interfacing a stepper motor with a Raspberry Pi:

- Raspberry Pi: Any model with GPIO pins will work, but for this guide, we’ll use the Raspberry Pi 3.

- Stepper Motor: NEMA 17 is a common choice due to its balance of torque and size.

- Motor Driver: Depending on the stepper motor, you might use an L298N, ULN2003, TB6600, or A4988 driver.

- Power Supply: A 12V or 24V power supply for the stepper motor.

- Connecting Wires: Jumper wires for connections.

- Breadboard: For easier connections and prototyping.

- Capacitors and Diodes: For circuit protection and stability.

Connection Diagram of Stepper Motor with Raspberry Pi

Connecting a stepper motor to a Raspberry Pi involves interfacing through a motor driver. Below are the connection details for different drivers:

Using L298N Motor Driver

The L298N is a dual H-bridge motor driver that can control the speed and direction of two DC motors or one stepper motor.

Connection Steps:

- Connect the Stepper Motor: Connect the four wires of the stepper motor to the output pins of the L298N module (OUT1, OUT2, OUT3, OUT4).

- Power Supply: Connect the external power supply (12V or 24V) to the L298N module. Connect the GND of the power supply to the GND of the Raspberry Pi.

- Control Pins: Connect the IN1, IN2, IN3, and IN4 pins of the L298N module to GPIO pins on the Raspberry Pi (e.g., GPIO17, GPIO18, GPIO27, and GPIO22).

- Enable Pins: Connect the ENA and ENB pins of the L298N to 5V (can be taken from the Raspberry Pi) or use GPIO pins if PWM speed control is desired.

Using TB6600 Stepper Motor Driver

The TB6600 is a more robust driver capable of handling higher currents, suitable for larger stepper motors like the NEMA 23.

Connection Steps:

- Connect the Stepper Motor: Connect the four wires of the stepper motor to the A+, A-, B+, and B- terminals of the TB6600 driver.

- Power Supply: Connect the external power supply to the VCC and GND terminals of the TB6600.

- Control Pins: Connect the DIR (direction), PUL (pulse), and ENA (enable) pins of the TB6600 to GPIO pins on the Raspberry Pi (e.g., GPIO23, GPIO24, and GPIO25).

- Microstepping and Current Settings: Adjust the DIP switches on the TB6600 driver to set the desired microstepping and current limit according to the stepper motor’s specifications.

Using A4988 Stepper Motor Driver

The A4988 is a compact driver capable of driving a bipolar stepper motor. It supports microstepping, which allows for smoother and more precise control of the motor.

Connection Steps:

- Connect the Stepper Motor: Connect the four wires of the stepper motor to the A1, A2, B1, and B2 pins of the A4988 driver.

- Power Supply: Connect the external power supply to the VDD and GND pins of the A4988. Connect the motor power supply (VMOT) and GND to the appropriate pins.

- Control Pins: Connect the DIR (direction), STEP, and EN (enable) pins of the A4988 to GPIO pins on the Raspberry Pi (e.g., GPIO20, GPIO21, and GPIO16).

- Microstepping Settings: Set the microstepping resolution by connecting the MS1, MS2, and MS3 pins to VCC or GND according to the desired resolution (full step, half step, etc.).

Also Read: Arduino Stepper Motor Control using L298N

Rotate Stepper Motor using Raspberry Pi

To rotate a stepper motor using a Raspberry Pi, you’ll need to write a Python program that sends the appropriate signals to the motor driver. The GPIO pins on the Raspberry Pi will be used to control the motor’s direction and steps.

Stepper Motor Python Program for Raspberry Pi

Here’s a sample Python program using the RPi.GPIO library to control a stepper motor with an L298N driver:

import RPi.GPIO as GPIO

import time

# GPIO pin definitions

IN1 = 17

IN2 = 18

IN3 = 27

IN4 = 22

# Set up GPIO mode

GPIO.setmode(GPIO.BCM)

GPIO.setup(IN1, GPIO.OUT)

GPIO.setup(IN2, GPIO.OUT)

GPIO.setup(IN3, GPIO.OUT)

GPIO.setup(IN4, GPIO.OUT)

# Define stepper motor sequence for full step

step_seq = [

[1, 0, 0, 1],

[1, 0, 0, 0],

[1, 1, 0, 0],

[0, 1, 0, 0],

[0, 1, 1, 0],

[0, 0, 1, 0],

[0, 0, 1, 1],

[0, 0, 0, 1]

]

def set_step(w1, w2, w3, w4):

GPIO.output(IN1, w1)

GPIO.output(IN2, w2)

GPIO.output(IN3, w3)

GPIO.output(IN4, w4)

def stepper_step(delay, steps):

for _ in range(steps):

for step in step_seq:

set_step(step[0], step[1], step[2], step[3])

time.sleep(delay)

try:

while True:

stepper_step(0.001, 512) # Rotate forward

time.sleep(1)

stepper_step(0.001, -512) # Rotate backward

time.sleep(1)

except KeyboardInterrupt:

GPIO.cleanup()

This program defines the GPIO pins for the L298N driver and sets up a sequence for stepping. The stepper_step function controls the motor by iterating through the step sequence.

Python Code for A4988

Here’s a Python program for controlling a stepper motor with an A4988 driver:

import RPi.GPIO as GPIO

import time

# GPIO pin definitions

DIR = 20 # Direction pin

STEP = 21 # Step pin

ENA = 16 # Enable pin

# Set up GPIO mode

GPIO.setmode(GPIO.BCM)

GPIO.setup(DIR, GPIO.OUT)

GPIO.setup(STEP, GPIO.OUT)

GPIO.setup(ENA, GPIO.OUT)

def stepper_step(delay, steps, direction):

GPIO.output(DIR, direction)

for _ in range(steps):

GPIO.output(STEP, GPIO.HIGH)

time.sleep(delay)

GPIO.output(STEP, GPIO.LOW)

time.sleep(delay)

try:

while True:

GPIO.output(ENA, GPIO.LOW) # Enable the driver

stepper_step(0.001, 200, GPIO.HIGH) # Rotate forward

time.sleep(1)

stepper_step(0.001, 200, GPIO.LOW) # Rotate backward

time.sleep(1)

GPIO.output(ENA, GPIO.HIGH) # Disable the driver

except KeyboardInterrupt:

GPIO.cleanup()

This code configures the GPIO pins for the A4988 driver, enabling precise control over the stepper motor.

Also Read: Stepper Motor Connection and Wiring

NEMA 17 Stepper Test

The NEMA 17 stepper motor is a popular choice for many DIY projects. It offers a good balance between size and torque, making it suitable for applications like 3D printers and CNC machines.

Testing the NEMA 17 with Raspberry Pi

To test the NEMA 17 stepper motor, you can use the same Python program as above with slight modifications for the motor driver used (e.g., TB6600 or A4988). Ensure that the current settings on the driver are appropriate for the NEMA 17 motor to avoid overheating or damage.

Example with TB6600

import RPi.GPIO as GPIO

import time

# GPIO pin definitions

DIR = 23 # Direction pin

PUL = 24 # Pulse pin

ENA = 25 # Enable pin

# Set up GPIO mode

GPIO.setmode(GPIO.BCM)

GPIO.setup(DIR, GPIO.OUT)

GPIO.setup(PUL, GPIO.OUT)

GPIO.setup(ENA, GPIO.OUT)

def stepper_step(delay, steps, direction):

GPIO.output(DIR, direction)

for _ in range(steps):

GPIO.output(PUL, GPIO.HIGH)

time.sleep(delay)

GPIO.output(PUL, GPIO.LOW)

time.sleep(delay)

try:

while True:

GPIO.output(ENA, GPIO.LOW) # Enable the driver

stepper_step(0.001, 200, GPIO.HIGH) # Rotate forward

time.sleep(1)

stepper_step(0.001, 200, GPIO.LOW) # Rotate backward

time.sleep(1)

GPIO.output(ENA, GPIO.HIGH) # Disable the driver

except KeyboardInterrupt:

GPIO.cleanup()

This example uses the TB6600 driver, where DIR controls the direction, PUL controls the steps, and ENA enables/disables the motor.

Control Stepper Motor with Raspberry pi using L298N

The L298N motor driver is a cost-effective solution for controlling stepper motors with a Raspberry Pi. It’s suitable for small to medium-sized stepper motors and can be easily interfaced with the GPIO pins of the Raspberry Pi.

Parts List and Wiring

- Raspberry Pi

- L298N Motor Driver

- NEMA 17 Stepper Motor

- 12V Power Supply

- Connecting Wires

- Breadboard

Wiring Diagram

- Connect the Stepper Motor: Connect the four wires of the stepper motor to the output pins of the L298N module (OUT1, OUT2, OUT3, OUT4).

- Power Supply: Connect the external power supply (12V) to the L298N module’s VCC and GND. Connect the GND of the power supply to the GND of the Raspberry Pi.

- Control Pins: Connect the IN1, IN2, IN3, and IN4 pins of the L298N module to GPIO pins on the Raspberry Pi (e.g., GPIO17, GPIO18, GPIO27, and GPIO22).

Python Code

The Python code provided earlier can be used to control the stepper motor through the L298N driver.

Raspberry Pi, Python, and a TB6600 Stepper Motor Driver

The TB6600 driver is a powerful stepper motor driver capable of handling higher current motors. It provides better performance and flexibility, making it ideal for more demanding applications.

Parts List and Wiring

- Raspberry Pi

- TB6600 Stepper Motor Driver

- NEMA 17 or NEMA 23 Stepper Motor

- 24V Power Supply

- Connecting Wires

- Breadboard

Wiring Diagram

- Connect the Stepper Motor: Connect the four wires of the stepper motor to the A+, A-, B+, and B- terminals of the TB6600 driver.

- Power Supply: Connect the external power supply to the VCC and GND terminals of the TB6600.

- Control Pins: Connect the DIR (direction), PUL (pulse), and ENA (enable) pins of the TB6600 to GPIO pins on the Raspberry Pi (e.g., GPIO23, GPIO24, and GPIO25).

Python Code

The Python code provided in the NEMA 17 stepper test section can be used with the TB6600 driver.

Control Stepper Motor with Raspberry pi using A4988

The A4988 driver is a compact and efficient solution for controlling bipolar stepper motors. It’s particularly useful for projects requiring microstepping capabilities.

Parts List and Wiring

- Raspberry Pi

- A4988 Stepper Motor Driver

- NEMA 17 Stepper Motor

- 12V or 24V Power Supply

- Connecting Wires

- Breadboard

Wiring Diagram

- Connect the Stepper Motor: Connect the four wires of the stepper motor to the A1, A2, B1, and B2 pins of the A4988 driver.

- Power Supply: Connect the external power supply to the VDD and GND pins of the A4988. Connect the motor power supply (VMOT) and GND to the appropriate pins.

- Control Pins: Connect the DIR (direction), STEP, and EN (enable) pins of the A4988 to GPIO pins on the Raspberry Pi (e.g., GPIO20, GPIO21, and GPIO16).

Python Code

The Python code provided in the A4988 section can be used to control the stepper motor through the A4988 driver.

Circuit Protection – Control Stepper Motor with Raspberry pi

When dealing with motors and electronics, circuit protection is crucial to prevent damage to components. Here are some recommended protection measures:

- Diodes: Use flyback diodes across the motor coils to protect against voltage spikes.

- Capacitors: Place capacitors near the motor driver power inputs to filter noise and stabilize the power supply.

- Fuses: Include fuses in the power supply line to protect against overcurrent situations.

- Heat Sinks and Cooling: Ensure that motor drivers like the TB6600 and A4988 have adequate cooling to prevent overheating.

Also Read: Micro stepping of Stepper Motor-Smooth and Accurate Movements

Power Supplies

Choosing the right power supply is essential for the reliable operation of stepper motors. The power supply must provide sufficient voltage and current for the motor and driver.

Selecting a Power Supply

- Voltage: Match the voltage rating of the stepper motor. Common voltages are 12V and 24V.

- Current: Ensure the power supply can deliver the required current. Check the motor and driver specifications for the current rating.

Example Power Supplies

- 12V 5A Power Supply: Suitable for smaller stepper motors and drivers like L298N and A4988.

- 24V 10A Power Supply: Ideal for larger motors and drivers like TB6600, providing better torque and speed performance.

Python Stepper Motor Library – Control Stepper Motor with Raspberry pi

Using a dedicated library can simplify the control of stepper motors. One such library is gpiozero, which provides an easy-to-use interface for controlling GPIO pins on the Raspberry Pi.

Installing gpiozero

sudo apt-get update

sudo apt-get install python3-gpiozero

Example Code with gpiozero

from gpiozero import OutputDevice

from time import sleep

# Define GPIO pins

IN1 = OutputDevice(17)

IN2 = OutputDevice(18)

IN3 = OutputDevice(27)

IN4 = OutputDevice(22)

# Define step sequence

step_seq = [

[1, 0, 0, 1],

[1, 0, 0, 0],

[1, 1, 0, 0],

[0, 1, 0, 0],

[0, 1, 1, 0],

[0, 0, 1, 0],

[0, 0, 1, 1],

[0, 0, 0, 1]

]

def set_step(w1, w2, w3, w4):

IN1.value = w1

IN2.value = w2

IN3.value = w3

IN4.value = w4

def stepper_step(delay, steps):

for _ in range(steps):

for step in step_seq:

set_step(step[0], step[1], step[2], step[3])

sleep(delay)

try:

while True:

stepper_step(0.001, 512) # Rotate forward

sleep(1)

stepper_step(0.001, -512) # Rotate backward

sleep(1)

except KeyboardInterrupt:

pass

The gpiozero library simplifies the GPIO pin control, making the code more readable and easier to maintain.

Conclusion

Controlling a stepper motor with a Raspberry Pi opens up a wide range of possibilities for DIY projects and professional applications. By using appropriate motor drivers, such as the L298N, TB6600, or A4988, and leveraging Python libraries like RPi.GPIO or gpiozero, you can achieve precise control over stepper motors.

Whether you’re building a simple project or a complex machine, understanding the basics of stepper motor control, from wiring and power supplies to Python programming and circuit protection, is essential. With the knowledge gained from this guide, you can confidently embark on your next stepper motor project using a Raspberry Pi.

By following the detailed instructions and examples provided, you should be able to set up and control your stepper motor, ensuring smooth and accurate movements. Happy building!