Stepper Motor RPM: How many RPM is a stepper motor

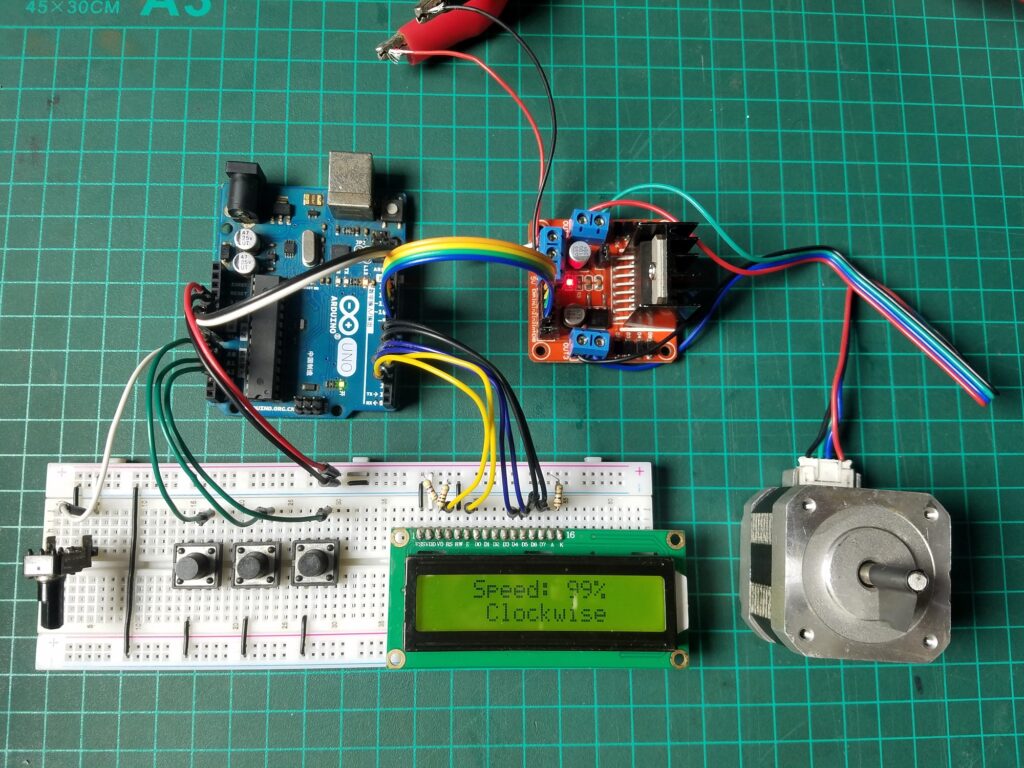

Stepper motors are known for their precise control over movement, making them suitable for applications requiring accurate positioning and speed control. The RPM (revolutions per minute) of a stepper motor is an important performance metric that affects its suitability for various tasks. In this article, we’ll explore how to determine the RPM of a stepper motor, the factors influencing it, and typical speed ranges for different applications.

Understanding RPM of Stepper Motor

RPM refers to the number of complete revolutions a stepper motor’s shaft makes in one minute. The RPM of a stepper motor is determined by the frequency of the pulses sent to the motor driver and the motor’s step angle.

Calculating RPM of a Stepper Motor

To calculate the RPM of a stepper motor, you need to know the following:

- Step Angle: The angle the motor moves per step. Common step angles are 1.8° or 0.9°, which correspond to 200 or 400 steps per revolution, respectively.

- Pulse Frequency: The number of pulses per second sent to the motor driver. Each pulse corresponds to one step of the motor.

Calculation Formula:

Where:

- Pulse Frequency (Hz) is the frequency of pulses sent to the motor driver.

- Steps per Revolution is the number of steps required for one complete revolution of the motor.

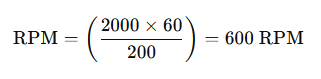

Example Calculation:

For a stepper motor with a step angle of 1.8° (200 steps per revolution) and a pulse frequency of 2000 Hz:

- Steps per Revolution: 200 steps

- Pulse Frequency: 2000 Hz

So, with a 1.8° step angle and a pulse frequency of 2000 Hz, the motor would operate at 600 RPM.

Also Read: Stepper Motor Torque: What is the torque of a stepper motor?

Micro stepping of Stepper Motor-Smooth and Accurate Movements

Factors Influencing RPM of Stepper Motor

- Motor Type and Design

- Stepper Motor Size: Larger motors or those designed for higher performance can achieve higher RPMs.

- Motor Design: The internal design and winding configuration can affect the maximum speed.

- Driver Capabilities

- Driver Specifications: The stepper motor driver must be capable of handling the desired pulse frequency to achieve the target RPM.

- Microstepping: Using microstepping can affect the RPM by allowing finer control but may reduce the effective speed.

- Load and Torque Requirements

- Load: Higher loads can reduce the motor’s maximum RPM due to increased resistance.

- Torque: The available torque decreases at higher speeds, impacting the achievable RPM under load.

- Power Supply

- Voltage: Higher voltages can improve the motor’s performance, including its RPM, by allowing faster current changes in the windings.

- Heat Dissipation

- Cooling: Effective cooling is essential for maintaining high RPMs, as excessive heat can reduce the motor’s performance and lifespan.

Typical RPM Ranges for Stepper Motors

- Low RPM Motors

- Applications: Used in applications like 3D printers and CNC machines where lower speeds are sufficient.

- Typical RPM: 200 to 1000 RPM

- Medium RPM Motors

- Applications: Suitable for general automation and robotics tasks.

- Typical RPM: 1000 to 3000 RPM

- High RPM Motors

- Applications: Used in applications requiring higher speeds, such as certain camera systems or high-speed machinery.

- Typical RPM: 3000 RPM and above

Practical Considerations

- System Compatibility: Ensure that the motor driver, power supply, and mechanical system are compatible with the desired RPM.

- Performance Testing: Test the motor performance under actual load conditions to verify that it meets the required RPM and operational specifications.

Conclusion

The RPM of a stepper motor is a critical factor that influences its suitability for various applications. By understanding the factors that affect RPM and using the calculation formula, you can determine the appropriate speed for your stepper motor. Typical RPM ranges vary from low (200-1000 RPM) to high (3000 RPM and above), depending on the motor’s design and application requirements.